- We Practice

Global Standards

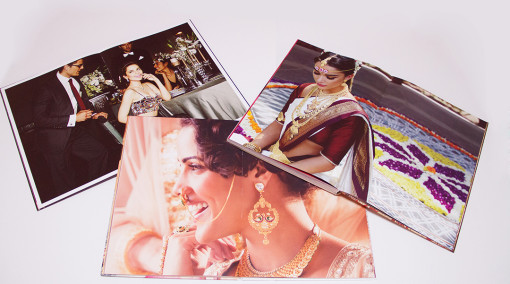

Know More - Reproducing

True Colours

see portfolio - high precision

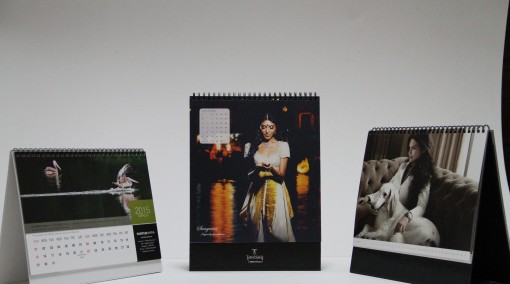

Finishing touches

see portfolio - Awards

That speak

View More

PLANNING

PRE-PRESS

PRESS

POST PRESS

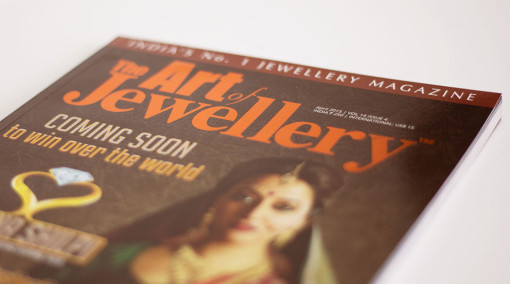

LEADING COMMERCIAL PRINTERS

SEVERAL NEW AND INNOVATIVE PRINT TECHNIQUES

PRINTING MADE EASY

CONVERTING YOUR IDEAS INTO CAPTIVATING PRINT

OUR QUALITY POLICY:

Vishwakala Printers recognizes that the maintenance of defined quality standards in all aspects of performance is critical to our success. As part of our Total Quality approach we are committed to a quality policy, which will assure our customers that our business as a whole achieves a recognized standard of performance.

Vishwakala Printers recognizes that the maintenance of defined quality standards in all aspects of performance is critical to our success. As part of our Total Quality approach we are committed to a quality policy, which will assure our customers that our business as a whole achieves a recognized standard of performance. We will invest as appropriate in both equipment and people to provide our customers with a cost effective solution to their print requirements.

details